They may not hold water but they’ll carry hay.

Your horses are not in stalls, right?

Western Horse Watchers Association

Exposing the Hypocrisy, Lies and Incompetence of the Wild Horse Advocates

Around the ranch

They may not hold water but they’ll carry hay.

Your horses are not in stalls, right?

How to connect a rope to a halter.

For leading and riding.

You can fit 20 bales of hay into your truck if it has an eight foot bed. Start with four bales in V-formation.

Next, lay six bales in the valley, all with the same orientation.

Repeat the process in the rear half of the bed.

The finished stack will resemble a cube.

It doesn’t obstruct your side-view mirrors and if you’re not going too far, ropes and straps won’t be needed. The feed store offers a price break at 20 bales so this is really great!

If your ranch has trees, you’ll probably want to keep a chainsaw around, along with fuel, cutting oil and a spare chain. Some day a tree will come down, due to age, weather or disease, and it won’t be the one at the far end of the pasture where nobody goes.

That’s your driveway and gate under there.

A case like this should be handled by professionals. It’s too much work and for an individual and too dangerous. You’d need a boom truck, bucket truck, chipper and variety of saws.

Don’t worry though, there will be cases where you can do the work:

Incidents like the one above can cost over $5000 in cleanup and repairs, and you can’t put them off due to their location. Another reason why you want to have some cash in a savings account.

If you have the right equipment however, expenses like that can be minimized.

Originally installed as a tie point for grooming and hoof cleaning, this post is now used for scratching and rubbing. It’s a 4 x 6 treated timber 8 foot long, cemented about 30 inches into the ground.

The metal loop at the top is known as a ‘shoulder nut ring bolt.’ The eye (above the ring) has been polished by these guys.

Tie points should be high enough and lead ropes short enough so the horse can’t step on the rope or get his leg over it. If you’ll be around while he’s tied, then maybe you can give him a little more slack. See if you can get him to stand quietly without tieing while you clean his feet.

If circumstances are such that you want to be able to untie him quickly, try the bank robber’s knot:

If water gets to your horses by way of PVC pipe, you’ll want to keep some tools and parts on hand for leak repairs, such as

Get parts for the various line sizes at your ranch (3/4″, 1″, etc). Keep these items in a dry place and away from sunlight.

Before you glue anything, make sure the parts are clean and dry. Remove rough edges from where the pipe was cut.

If the leak is underground in a straight run of pipe, you won’t be able to replace the faulty section directly. Instead, reroute the line with some elbows, to create a flexible loop that reconnects to the old pipe at the points where you first cut into it.

You can also install a tee and riser to provide a branch connection for future use.

If your system uses copper tubing, you’ll want to keep the same assortment of fittings and valves, along with a cutter, propane torch, solder, and flux. Copper tends to be more durable than PVC so you probably won’t be making many repairs. But pipe fitting and soldering take a little more skill compared to PVC.

Don’t forget to order a spare bulb for your UV unit. It should be replaced annually.

If you have galvanized pipe panels with butterfly clamps, make sure the bolt head faces the area where your horses are. If that’s not feasible, cut off the threaded end and grind smooth so your horses won’t get hurt.

You can get them at Barn Light Electric Company.

Prices have come down and lead times have shortened.

Use them to accent your barn, illuminate a hose station, or light the way to your tack room.

Don’t.

It’s a great way to corrupt your relationship, leads to bribery.

Do you have to bring cookies to catch him in pasture? To put on a halter? Might as well place a sticker on your forehead that says KICK ME I’M LOWER.

Watch the video on the Oatman burros, especially the action from 2:22 to 2:38 where the burro is a bit too aggressive. Do you identify with that woman? Who’s moving whose feet?

You want your horse to see you as his leader not a walking talking vending machine.

You want him to come to you respectfully and pay attention, not frisk you with his nose.

Don’t set an expectation of food when it’s time to work.

If you want to give him carrots, cookies and apples, put them in his grain bucket.

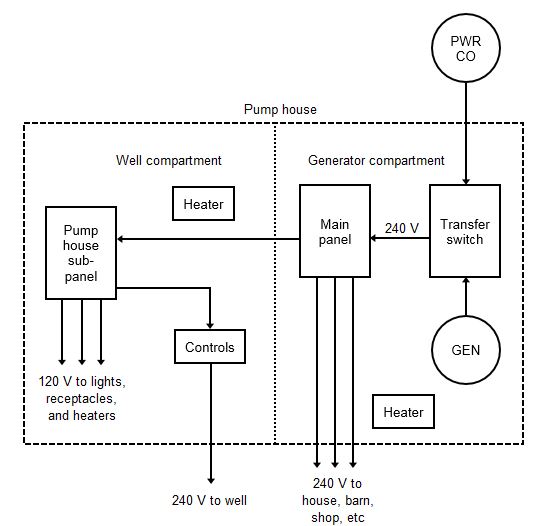

Your water system should have a back-up power source, such as a generator. If the pump in your well can’t run, you only have what’s in your pressure tank(s). And the power will probably go out when you’re just a few psi above the low setpoint of the pressure switch.

Ideally, the generator would be large enough to serve everything at your ranch, which means 15 to 20 kW in size. A smaller unit, say 10 kW, might require some load shedding before startup.

You’ll have to install a transfer switch to prevent back-feeding the power company. It can be manual or automatic.

If your generator can carry the full load of your ranch, the transfer switch can be automatic, along with startup of the generator.

A manual switch lets you reduce load before starting the generator. The sequence might look something like this (power already out):

At this point lights should come back on, the refrigerator should run, and your pressure tanks should refill when the low setpoint is reached.

When power is restored (numbers appear on face of electric meter), the sequence might be:

Load has now been transferred back to the power company. If your generator has a fuel tank, top it off so you’ll be ready for the next outage. Keep several five-gallon containers of fuel on hand and store in a safe location.

One way to keep electric demand low (and get by with a smaller generator) is to have ‘fired’ appliances, such as your water heater, furnace, cooktop and clothes dryer. Fuel can be natural gas (if available at your location) or propane. A stove that burns wood or pellets is another option.

A ‘poor man’s version’ would be to install the transfer switch at the panel that feeds the pump and connect a portable generator there. Allow 2 kW for a 1 HP pump, 4 kW for 2 HP pump, etc. It won’t power anything else but at least your horses will have water. The UV unit in your treatment system will be inactive, and the softener will not regenerate if it has electric controls.

Always make sure the exhaust from the generator is routed to a safe location. Never run it inside an occupied space such as a house or barn.

You can buy a trickle charger for the battery in your generator to make sure it’s ready to go when you need it.

Two basic types:

Here’s an example of each, side by side. Bow on the left, swing on the right.

A six foot bow gate with one-hand latch gives you easy access when you’re entering the corral with halters or fly masks in the other hand. Also gives you quick access to the poop pile when dumping the wheel barrow. Place the gate so the latch is on the outside of the corral.

The latch has a slider and keeper. To open the gate, flip the keeper up (on the right in the following photo) and pull the slider to the open position. The gate will swing freely in either direction.

If you are new to horses or are in the process of gentling some mustangs, always open the gate inward. Pull the slider open, push the gate in a few inches, then move the slider back to the closed position. If a horse approaches the gate as you enter and pushes, it will swing back and hit the bow, stopping it from flying open, knocking you to the ground, and setting your horses free. (This is one way your horse tells you he thinks you’re lower, that he doesn’t have to listen to you. It’s not a problem of smacking him and showing him who’s boss, it’s a problem of relationship. Yes, you may have to turn up the pressure for a while until he comes to you respectfully, the same way he would to a higher horse in his band.)

Unlike bow gates, swing gates are usually not furnished in a frame. You’ll have to cement 6 x 6 posts to hang them. Once they’re in place, you can bring in fill material with your tractor to create a dry space in the corral. Twelve feet wide should work. Orient the hinge post so the dead weight of the gate will not bend it (lines of grain parallel to gate in closed position).

You’ll also have to supply a latch for the gate. It can be mounted on the 6 x 6 post opposite the hinges. In the following example, you can reach through the gate to lift the inside keeper and push the gate open. If a horse pushes back or the wind blows it toward you, the outside keeper will stop it from flying open. It’s a great safety feature.

The latch will also allow the gate to open outward (not recommended unless you have halters on your horses and are taking them out to pasture or going on a ride). Some gates are furnished with chains for added security.

Avoid gates with chains only, no latches. They require two hands to secure properly.

Here’s another view of the two gates. Note the absence of 90 degree interior corners.

If you will be leaving your ranch for a few hours or retiring for the evening, check your gates to make sure they’re properly latched. And don’t think your horse won’t notice if they aren’t. If he doesn’t hear the ‘clink’ of the keeper dropping into position when the gate closes, he’ll probably walk over to investigate. If it’s the outside keeper, pasture is just one push away!

Opening and closing gates is not complicated. But on a ranch you’re doing that many times a day so it’s easy to mess up, especially when you’ve got a hundred other things on your mind.

Now that you have water at the surface and under pressure, should you send it directly to your horses? To answer that question, take a sample to your water treating supplier or lab that specializes in domestic water sources.

Your sample will be tested for three characteristics:

Suspended solids are small particles that make your water look cloudy. These can often be removed by settling and/or filtration.

Dissolved solids, sometimes referred to as ‘hardness,’ are minerals that leave a white residue on things when the water evaporates. The most common types are calcium and magnesium. They can’t be removed by filtration but can be removed by ion exchange (a.k.a. softening).

Microbes, such as bacteria and algae, can make your horses sick. They can be killed by UV radiation or bleach.

The treatment process usually begins with a filter, which removes suspended solids from the incoming water. As silt and sediment accumulate in the filter, pressure loss goes up and water flow goes down. If your water buckets are filling slowly, check this filter, it may be time to replace the element.

You’ll want to keep spare filters and O-rings on hand. Dirty elements can be cleaned and reused once or twice. You can buy filters and parts at vendors like this one.

Softening is the next step in the treatment process. Most units have a resin bed with brine tank. The resin has millions of tiny beads which initially hold particles of sodium. Water flowing across the bed picks up sodium from the resin and loses calcium and magnesium.

Eventually, the resin becomes full of calcium and magnesium, which are displaced by sodium in the regeneration cycle. Salt in the brine tank provides the sodium.

A problem with single-bed units is timing of regeneration. The control panel lets you decide when that happens, usually at night when water use is low. The bed may or may not be exhausted at that time.

In the summer, you’ll be putting out more water for your horses, spraying them down for cooling, washing out your trailer, etc. You may run out of soft water before the unit regenerates. That problem can be avoided with a dual-bed system.

Keep in mind that soft water still contains dissolved solids and may leave a residue if the water is allowed to evaporate completely.

Next in line is a charcoal filter, which improves taste and removes odor. Unlike a softener, this unit can’t be regenerated; it must be dumped and refilled with new media or receive a new cartridge. A ‘whole house’ unit may run for several years before needing service.

The softener and charcoal bed may be followed by another filter which removes fine particles from the water. Elements in this unit may be rated for 5 microns, whereas the filter at the beginning of the train may be around 20 microns. The rating tells you what size particles the element will catch. A micron is a thousandth of a millimeter.

The last step in the treatment process is microbio control. A rural water system will often use an ultraviolet unit to kill microbes before sending water to users.

Although UV radiation is effective at the point of application, it can’t send the kill down the line.

If microbes were present before you installed the unit, they will still be there. You can treat the entire system by dropping a few bleach tablets into the well. It only takes a few ppm (parts per million) of bleach to do the job. Check with your well contractor or water treating supplier.

Your horses will probably be happy with their water at this point. If you’ll be consuming it, you can install an RO unit under your kitchen sink to provide an additional layer of protection.

In reverse osmosis, water is forced under pressure through a membrane that allows water molecules to pass through but not much else.

The RO unit will likely have cartridge filters in addition to the membrane that should be replaced on periodic schedule.

A problem with some RO systems is waste. You may have to feed three or four gallons of soft water to get a gallon of drinking water out. Contaminants held back by the membrane are swept out of the system and down the drain by the ‘missing’ water.

Never send raw water from your well directly to the unit. Without pretreatment, silt, sediment and minerals will foul the membrane quickly.

The tee at the base of your pressure tank probably has a 1/4 inch tap for a pressure switch, along with other connections for a relief valve, drain valve and pressure gauge.

If you only have one such tank, you can install the pressure switch on the tee.

If you have several tanks in parallel (recommended), mount the pressure switch on the line that feeds the tanks. Some day you will want to isolate and drain each tank to remove sediment and check the air pressure in the upper chamber. But you don’t want to shut the entire system down to do it.

The only valve normally closed in the diagram above is the bypass. In colder climates, the valve at the exterior hose bibb would be closed during the winter, and water trapped between the two valves would be drained. If your horses stay off the pasture in the winter you might close that valve as well and drain the line for freeze protection.

This pressure tank is in the loft of a barn. It is one of several that ‘ride the line’ between the well and treatment system. Note the tap for the pressure switch is plugged.

To service the tank, you’d shut the valve on the left and open the drain valve near the pressure gauge. Connect a hose to the drain valve to route the water to a safe location. Remember, it’s still under pressure even though the isolation valve is closed!

You’ll need 120/240 VAC for your water system. The motor on your pump probably runs on 240 volts. Equipment in your pump house likely needs 120 volts but in colder climates you may also need 240 volts for a space heater.

Your contractor will likely install a device that automatically shuts off the pump if it detects low flow or dry running. If it activates you may have to reset it manually. The device may be located near the well or in the pump house with other controls. Ask your contractor so you’ll know what to do when the time comes.

If everything works properly, you’ll have a reliable source of water for your horses.

You’ll only have to worry about a power outage and that won’t be a problem if you have a back-up generator (to be considered in a subsequent post).

The greatest gift you can give your mustang is patience.

Remember, he’s been chased by helicopters, probably for several days, jammed into a chute and freeze-marked, had his boys cut off, brusquely handled by wranglers, and hauled off to an alien world.

Now you want to put him in a confined space and try to make friends when he doesn’t trust you and is ill-prepared for the experience?

How do you give him release when your presence is pressure?

What kind of learning happens in this environment?

The first thing you have to do is sack him out to you.

Let him come to terms with his new surroundings on his own timeframe. Spend some time with him doing chores (scooping poop and filling water buckets). Give him a chance to figure out you’re not a threat. The older he is the longer this will take.

An exception might be when he is aggressive and dangerous (because he was taught bad lessons by someone else) and will be put down or sold at auction.

It’s not the rope.

He’s not flighty.

It’s you.

If your water system is supplied by a well, it must have at least one pressure tank. The tank has two chambers. The upper section is filled with compressed air, the lower section holds water from the well. The water chamber usually has a rubber liner that provides a flexible diaphragm between the two chambers (like a balloon).

As water flows into the lower chamber, the diaphragm expands and pushes against the air, which is compressed in the upper chamber. The air pushes back against the diaphragm.

This maintains system pressure.

When you fill water buckets for your horses, air in the upper chamber pushes water out of the tank and into your system. Check valves in the discharge line from the pump make sure water doesn’t go back into the well.

When the system pressure drops below a pre-set point (determined by the pressure switch), the pump cuts in and refills the tank.

Pressure tanks are usually installed on the ‘raw’ side of the system, that is, upstream of the treatment equipment. More on that in a subsequent post.

You probably want a pressure tank that holds at least 20 gallons of water. The more capacity you have, the fewer on/off cycles for the pump, which extends its life. You can install pressure tanks in parallel for more storage. A horse ranch should have at least 40 to 60 gallons of water under pressure. Install a valve at each tank so it can be taken off-line without shutting the system down.

Vendors such as this one offer a range of pressure tanks and parts.

Tanks must be emptied of water before setting the air pressure in the upper chamber, which should be two psi below the ‘low’ setpoint of the pressure switch. If your switch turns the pump on at 40 psi water pressure, set the pressure in the upper chamber to 38 psi.

Pressure tanks often have valve stems on top similar to those on the tires of your car. You can use the same tool to check the air pressure in your tank(s).

If you live on a ranch, you may have a portable compressor for keeping the tires of your tractor properly inflated. You can use the same machine to service your tank(s).

In some areas, large non-pressurized tanks may also be required to provide water for fire protection. For example, a 5000 gallon poly tank with roof, or two 2500 gallon poly tanks in parallel. Water in these tanks might sit there for weeks or months.

Bulk tanks don’t store water under pressure. You’ll need a booster pump to supply the firewater system.

If these tanks provide water for your potable system, the booster pump would send water over to the treatment equipment and then out to your horses.

In both cases, the tanks would hold untreated (raw) water from your well, taken from a point downstream of the pressure tanks.

Your pump may run for several hours when filling a bulk tank. Make sure you’re not drawing water out of the well faster than it flows in!

Go to this FB page for the latest on the rescue, now in its final stages. A home is needed for twenty aged and/or blind stallions.

The story of the ISPMB rescue appears on a related FB page.

Three cheers to Elaine Nash and her team at Fleet of Angels, along with Palomino and Matt Armstrong of Chilly Pepper Miracle Mustang!

The ISPMB sanctuary included horses from White Sands NM, Gila Bend AZ, Virginia Range NV and Sheldon National Wildlife Refuge NV.

Now that you found water on your property, you’ll have to bring it to the surface.

If the water level is 30 feet down or less you can install a pump at grade. This would also apply to water drafted out of a spring or pond. Keep in mind that surface water is more susceptible to contamination than ground water.

A surface-mounted pump should be self-priming, which means it can draw water from the source even if the suction line is empty.

If the water level is below 30 feet, the pump will have to go down hole. It has to do three things:

Suppose you drilled your well to 480 feet. You hit water at 420 feet and the static water level is at 360 feet.

You don’t want to install the pump at the bottom of the well. Leave some room for accumulation of silt and sediment. At least 20 feet. That puts the pump at 460 feet. Although the water level is 100 feet higher, the worst case is when you pull water too fast and drop the level down to the pump.

This brings up the concept of recharge rate. Water enters the well through perforations in the casing. You don’t want to draw water out faster than it flows in. At least not for long. Running a pump dry will destroy it.

Your driller can perform a test to determine the recharge rate.

The system pressure is controlled by a switch that turns the pump on and off automatically. Typical pressure range is 40 to 60 pounds per square inch (psi). On at 40, off at 60. Greatest pressure is therefore 60 psi. As you use water, the pressure in the system drops until the pump kicks in and refills the tanks.

The amount to allow for pipe friction depends on the water flow rate, pipe size, and length of discharge line (depth of pump plus distance from well to pressure tanks). If the line is properly sized, this number will be small. Start with 5 psi.

Summary of conditions for this example:

Pumps curves are based on feet not psi. To convert, multiply psi by 2.3 to get feet.

Total head = 460 + (60 × 2.3) + (5 × 2.3) = 610 feet

Round to 600 feet to keep things simple. Here are curves for Goulds series 7GS pumps.

Start on the y-axis at 600 feet and move to the right. When you hit a curve read down to the x-axis. A 7GS15 pump will give you about 5 gpm. A 7GS20 will give you 8.5 gpm. A flow rate of 5 to 10 gpm should be adequate for you and your horses. Boarding facilities and farms require something larger.

You probably have water under your property. Technologies are available to help you find it but you might pay over $10,000 for the work. Old-timers in the area may know where to drill based on their experience.

Another idea is to look at public records (driller’s reports) for nearby parcels.

Keep in mind that if you drill at the low spot on your property you will be pushing water uphill which means lower pressure the higher you go. Not really an issue on ground that’s fairly level but if you live among rolling hills, where your corral and arena are 80 feet above the wellhead, you’ll lose about 35 psi by the time water gets to your horses.

No wonder it takes 10 minutes or more to fill a water bucket!

Conversely, if your wash rack is 80 feet lower than the wellhead, water may come out of the sprayer with so much force that it’s dangerous to your horse.

Water pressure typically ranges from 40 to 60 psi at the wellhead. More about that in the next post.

Your driller will recommend an appropriate casing. Sometimes it’s PVC, as shown in the Intro. The casing below is steel.

Your driller will also decide how far to go. Usually 50 feet or more beyond the point where water is found.

He will install solid or perforated casing as needed, backfill the space around the casing with sand or gravel, and seal the uppermost portion of the bore with cement.

The bottom of the casing is usually left open, in case the well goes dry and you have to dig deeper.

Subsurface pressure may push water up the casing. Suppose you hit ‘pay dirt’ at 400 feet but water inside the well is at 340 feet. This is known as the static water level.

Cost to drill depends on several factors but you can start with $40 to $45 per foot. If your well is 500 feet deep, you will pay at least $20,000. This does not include the pump, controls, or anything else.

You can’t have horses on your property without a reliable source of water.

Parcels large enough for horses are usually not connected to the public water system.

So you have to provide your own water.

You must be able to give your horse clean fresh water daily, hot or cold, rain or shine.

A rural water system will likely have these components:

Here’s what you might see in warmer climates (small risk of freezing temperatures for more than 8 to 12 hours). Well, pressure tank & switch, power supply & piping exposed to the elements.

Other measures are required for colder climates, to be considered in subsequent posts.